Utility waste at manufacturing plant is a choice, money is not the issue

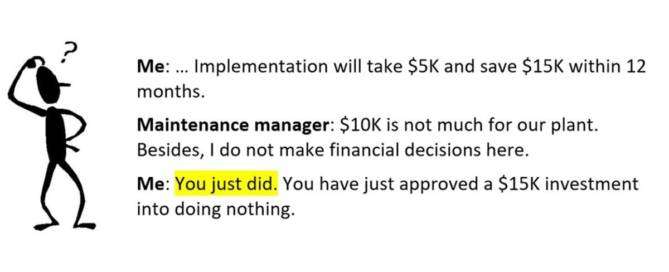

I often hear that "Energy audit costs money, but saves no energy". This is true and not true at the same time. Here is why: Any experienced plant manager knows that their plant wastes utilities. No shame in this. Every plant wastes energy. Few plant managers know where exactly this waste occurs and even [...]