Energy audit takes time and costs money, is it worth the effort? How do I know if it will uncover enough saving opportunities?

To quickly estimate how much money can be saved on utilities, we have devised an express tool – Energy Management Score assessment™. EMS is based on a premise that the way management approaches energy determines how much energy is still wasted. Assessment compares energy management practices at a plant to the best practices summarised in ISO 50001. Value of using best practices has been proven by analysis conducted by 3M and Schneider Electric at their plants: certified plants achieved 62% higher energy savings. 3M Canada has achieved 96% score at EMS.

How does EMS forecast compare to results of full scale energy audit?

We run EMS at our client before conducting a full-scale utility audit. This plant runs an energy intensive production process with $2mln utility budget. A 25-min assessment predicted a possibility to cut energy cost by $300-400K. A full-scale utility audit produced a list of specific projects totalling $533K, including $83K worth of projects with combined required investment of $9K.

EMS estimate at food plant: $300-400K savings. Energy Audit estimate: $533K savings between 12 projects

What professionals say about Energy Management Score Assessment™?

We invested several months to carefully design, clearly word, and then code this assessment. Then we asked respected industry professionals to review it. Here is what they said:

Andrew Hejnar, P.Eng, MScEM, CEM, Energy Manager at 3M Canada:

“EMS assessment uncovers core issues of energy management through a series of simple questions directly related to business. I particularly like how it links quality of practices with results. It’s a handy tool to start or rekindle an energy management conversation in the boardroom.”

Barry Staddon, Assistant General Manager at Magna powertrain (MSM):

“The Energy Management Score assessment is simply-worded, engaging and thought-provoking. The questions compare current business practices to energy management best practices and provide the all-important gap analysis that fuels the drive for improvement.”

David Elfstrom, Energy Management & Conservation Engineer

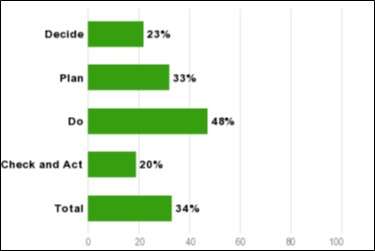

“The assessment is simply worded, it’s easier and faster to complete compared to energy management matrix that is used in some NRCan materials. I like how it is linked with Plan-Do-Check-Act model.”

Find out how much your plant wastes on energy

But do not take their word for it – try it for yourself and form your own opinion.

For time being EMS assessment is available through self-service at no cost at Energy Management Score assessment™ – EMS.

It’s a multiple choice questionnaire that does not require calculations or special knowledge. In 25 min you will receive a 126-word pdf report with an estimate of how much you can save better managing your energy.

Leave A Comment