Welcome to our blog: How Energy Management Affects Your Business and Profit

Dear visitors, we welcome you to our blog. We write for owners, business and financial managers, energy engineers, who want to find ways to benefit their Business, Clients and Environment through energy management. From our experience we can assure you: energy management will help you can gain much more than just reduce energy costs. Here you will find energy [...]

Revolutionizing Energy Management of Big Portfolios: kWIQly’s AI Saves Time, Energy, and Money

In the world of property management overseeing energy in big portfolios of small but numerous sites is a daunting challenge. No manager can afford to watch energy consumption every day at every site while energy costs are up, and maintenance resources are limited. Enter kWIQly, a cutting-edge AI platform that is here to revolutionize energy management of big portfolios [...]

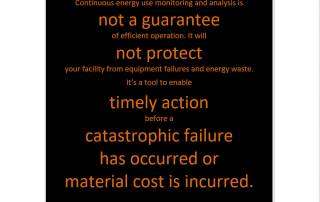

Continuous monitoring of energy will not ensure savings or protect from failures

As a facility manager, are you responsible for ensuring that your operations are running smoothly and efficiently? One important aspect of this job is to ensure meeting energy use reduction targets. Monitoring energy usage is commonly offered as a tool to reach energy and CO2 reduction targets. However, even a continuous energy use monitoring and even analysis do not [...]

How do you know if your energy retrofit has delivered results promised by the vendor?

Let me tell a story without naming names. I believe it to be very typical for the Ontario market. Some business was convinced they had the most energy efficient operations in the world. Why wouldn't they be if they had installed energy-efficient equipment provided by the reputable vendor? However, an old owner had a gut feeling that their energy [...]

Energy retrofits fail because of weak energy management, not because of technology

Quality of energy management defines quality of energy retrofits. Finding ‘why’ energy is wasted is pivotal to determining how to fix the issue. Energy management is the key to unlocking utility savings and reaching carbon reduction targets. But how do you know if your energy management practices are up to par? A simple way to find out where your [...]

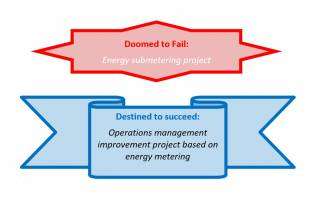

Why many energy submetering projects fail … and how to ensure that yours succeeds

'Energy submetering project' is doomed to fail unless it is a 'data-based operations management enablement project'. With energy submeters getting cheaper, setting up a submetering project is a no-brainer and not a big deal, right? - Sure, if your sole goal is to spend money on new meters. It's a different story if your goal is to create value to your [...]

Energy waste in a quick service restaurant is worth the owner’s attention

Cost of saved energy directly adds to QSR owner's profit

Energy waste in a quick service restaurant can be found at a cost of burger, fries, and a pop

In the previous post we have established that cutting energy cost in quick-service restaurant is well-worth owner’s attention. We have also established that about 80% of electricity and 100% of natural gas are consumed by refrigeration, cooking, HVAC, and water heating, with refrigeration and cooking leading in both categories. These are all areas where hard-to-notice malfunction or operational error [...]