In Energy Management Action without Information is a Waste of Resources

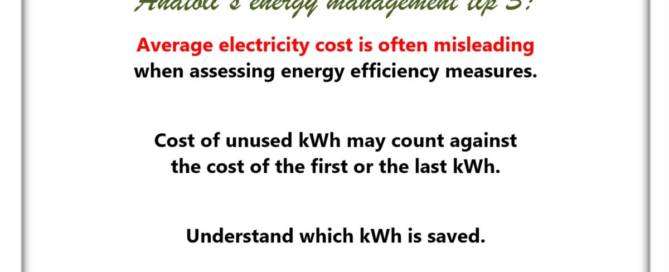

A conventional wisdom suggests that only action creates results. I tend to agree, except that is must be a correct action. How do you what energy project is the right one? How to choose between projects when each vendor claims attractive savings? I do not have a crystal ball either, but I [...]