In this post we shall conclude describing how 3M has achieved outstanding energy cost reduction results. These publication has resulted from interview with Andrew Hejnar, Energy Manager of 3M Canada. This post completes the story started in previous publications:

Tip 1: Secure high-level support for energy projects as soon as possible.

Energy touches every aspect of manufacturing process. Changes require will, coordination, and cooperation, not to mention funding and resources. All these are much easier to secure with a high-level champion.

Tip 2: Involve utilities.

Energy efficiency specialists at utility companies are involved in dozens of projects that may benefit your plant. These people are willing and available to help find projects, provide temporary metering equipment, and to form projects in a way to secure the most incentives.

‘A plant walk-through with a utility rep often opens a different perspective’, – Andrew Hejnar, 3M Canada.

Tip 3: Energy management is a team game.

Energy links all equipment and most manufacturing processes. Every process requires energy. Thus, to be successful, energy management must be a collaborative process as well. A plant may invest thousands/millions in highly efficient machines; still a sloppy operator or an outdated procedure may waste all the savings. On the positive side, joining forces with existing plant-level sustainability specialists may help HQ implement an energy project faster, because local people know local ways to get things done.

Conclusion: 3M’s best kept secret is no secret after all

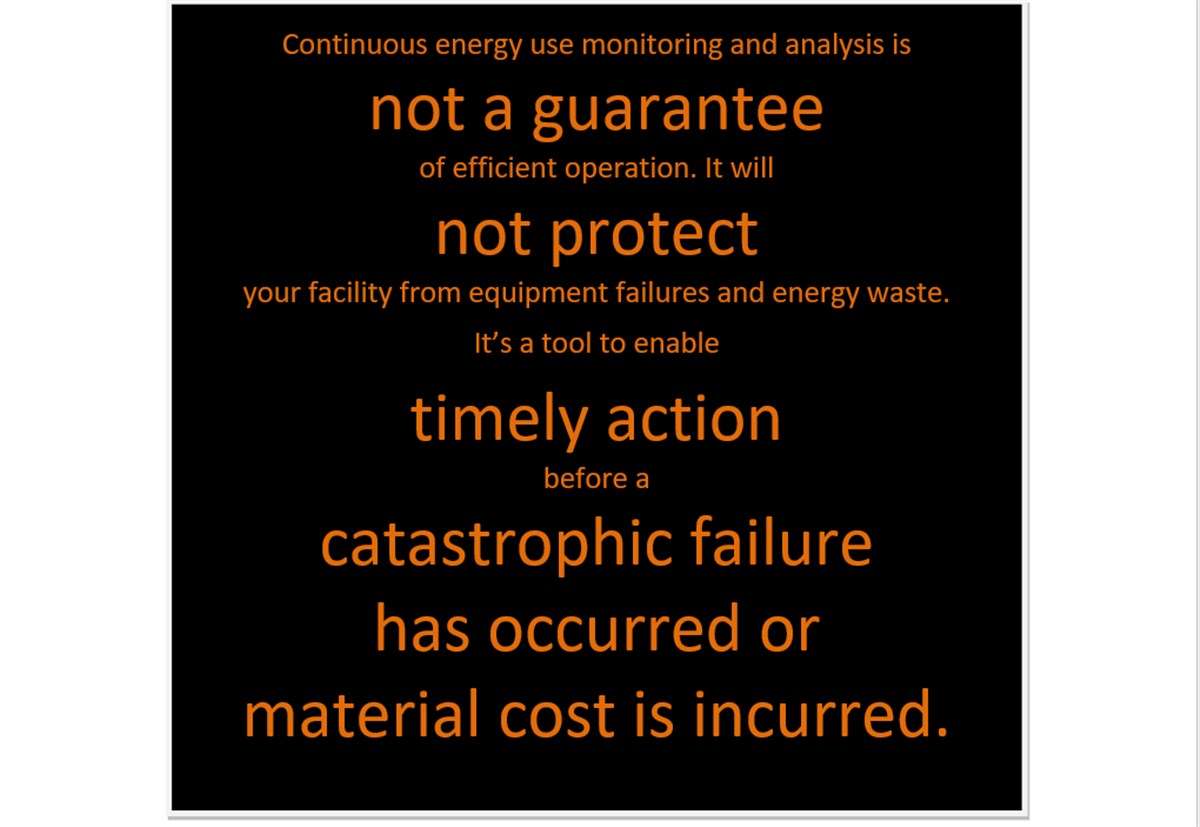

The main secret of 3M’s success in energy management is that there is no secret at all. It’s just management applied to energy.

In ‘energy management’ the key work is ‘management’, not ‘energy’.

Judging by results, consistent implementation of best practices, team-based innovation and accountability based on measurement effectively guarantee outstanding results. These are well-known basic principles of management in any area. They simply work.

What can you do to replicate 3M’s success in energy management?

To find out how well does your scores vis-a-vis energy management best practices and how much can your plant cut energy costs, we have developed an Energy Management Score™ assessment – a free online tool.

3M Canada scored 96% on EM Score™ and has reduced utility bills by 32% over 8 years. What is your score?

Take a test at Energy Management Score™ Assessment. It takes only 15 minutes to find your score.

Subscribe to our blog to ensure you do not miss our next publications.

[…] Home/Energy management, Energy management education, Interesting Reads/How has 3M Canada cut energy use by 32%? Part 5: How does 3M evaluate and monitor energy projects? Previous Next […]