Procurement department can buy materials, machines and office supplies, but cannot buy electricity, natural gas and water. Just can’t. Does not have sufficient decision-making authority. Neither does CFO. Nor even President.

Utilities are bought by a person who flips the switch or turns the valve, not by procurement or CFO or President.

Procurement contract for parts, materials and services determines how much is bought, when it will be delivered, at what price per unit and at what total cost.When it comes to utilities procurement department (CFO, President) can only somewhat negotiate tariffs, but cannot determine when utilities will be delivered and how much it will cost by the end of the month. In fact, procurement knows the final cost only when bill arrives. No other goods are procured this way.

A radically different situation calls for a radically different approach to managing costs of electricity, natural gas and water. Cost can only be managed by people who actually make buying decision – production operators and managers. Unless utility cost affects plant manager’s performance scorecard, procurement can’t do much about cutting utility cost.

How is electricity bought on production floor?

Let’s consider a simple example of how on-floor procurement works at a plant that uses 5 machines (fan, pump, compressor, etc) with 200 kW nameplate capacity and average draw of 100 kW. All machines are required for production and all are turned off until shift starts. Typically during first minutes of operation demand is close to nameplate capacity and then demand lowers the level required for production.

If operator flips a switch of all machines at the same time the demand will peak to 1,000 kW. If the same operator starts machines with a proper delay, the peak will be at 100*4+200= 600 kW. Good bye 400kW peak charge. Procurement can’t control this. CFO can’t control it. President can’t control it. Wait. President can’t directly control it, but President can make Plant Manager responsible for energy cost and make sure Plant Manager understands the value of peak charge.

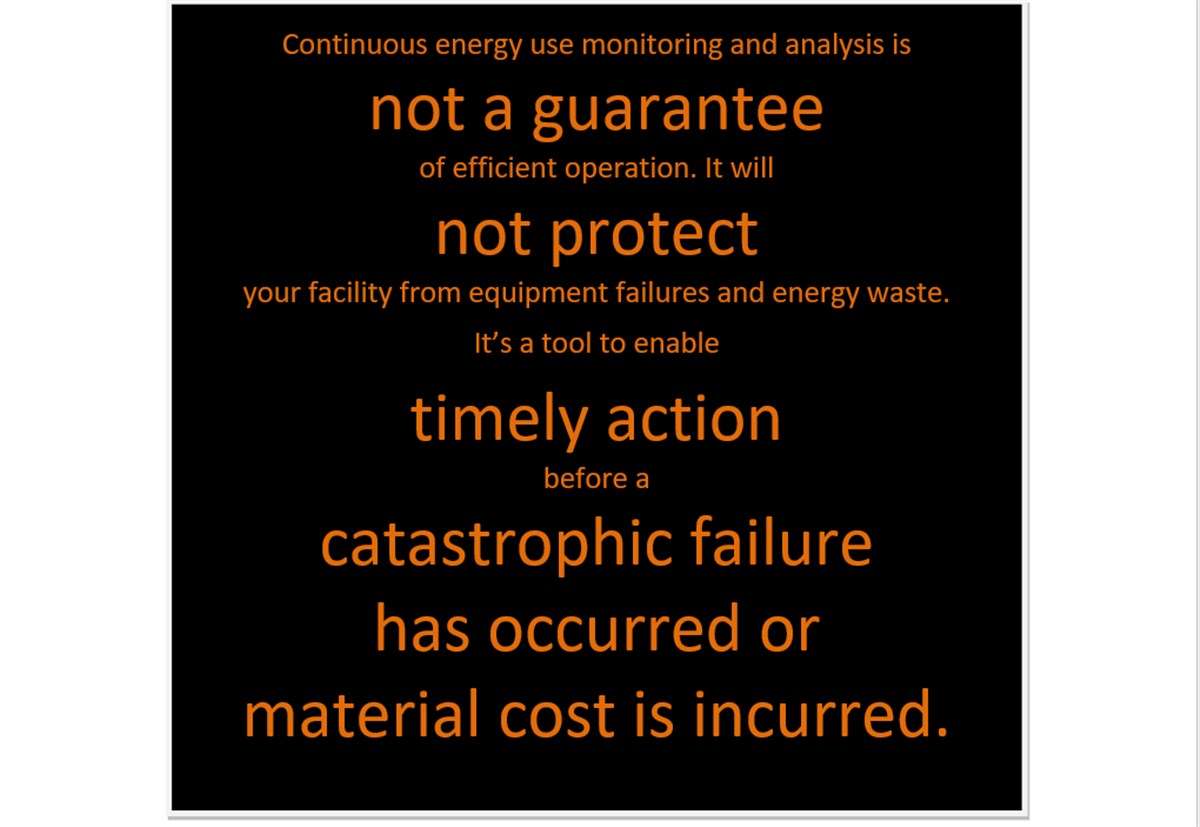

Energy Management is management applied to energy use, not only to energy cost.

When does consumption at your plant peak?

How much does it cost?

Does it have to be that high?

[…] Machines are routinely left running because energy is invisible. Energy procurement is done by production floor personnel, not by CFOs: procurement effectively happens when switch is turned, not when contract is signed. […]