A lot is being said about the need to manage energy. Many of our contacts seem confused about this idea and often do not know where to start. Here is a relief: energy management is first of all management, all rules apply. To demonstrate we will project management ideas to energy context.

A business needs to know how to manage its energy uses efficiently in order to thrive or to survive. For example, in February and March of 2014 natural gas prices spiked 25-fold during some days. This increase in cost became a financial burden for all businesses. Several companies shut down because of the steep rise. Others suffered devastating blows to their profits.

Energy management is crucial in a company’s survival. The problem is that many companies do not know how to start creating an energy management plan. Luckily, energy management is part of management and trusted-and-true rules apply. Consider the following procedures a guideline to permanent fuel sufficiency:

- Measure

Measuring the company’s use of natural gas and electricity provides an accurate picture of what happened and allows calculating production cost. Accurate consumption measuring is a basis of all next energy management steps. Measurement and management go hand in hand. What works for raw materials and labour, works for natural gas and hydro.

- Analyze

Production and weather are known to drive utility consumption. Unfortunately non-production consumption is sometimes way higher. Finding out the key consumption drivers at your facility is the key to setting up energy management plans and priorities. Analyzing utility use is similar to blood work: every process at manufacturing facility uses energy in the same way as every process in human body affects blood.

Utility bill is a good start, though submetering often uncovers vast saving opportunities.

- Forecast

Understanding what drives the utility consumption at your facility in combination with production plans and weather forecast allows predicting the future consumption of natural gas and electricity. This prediction is a key to active energy management.

- Act

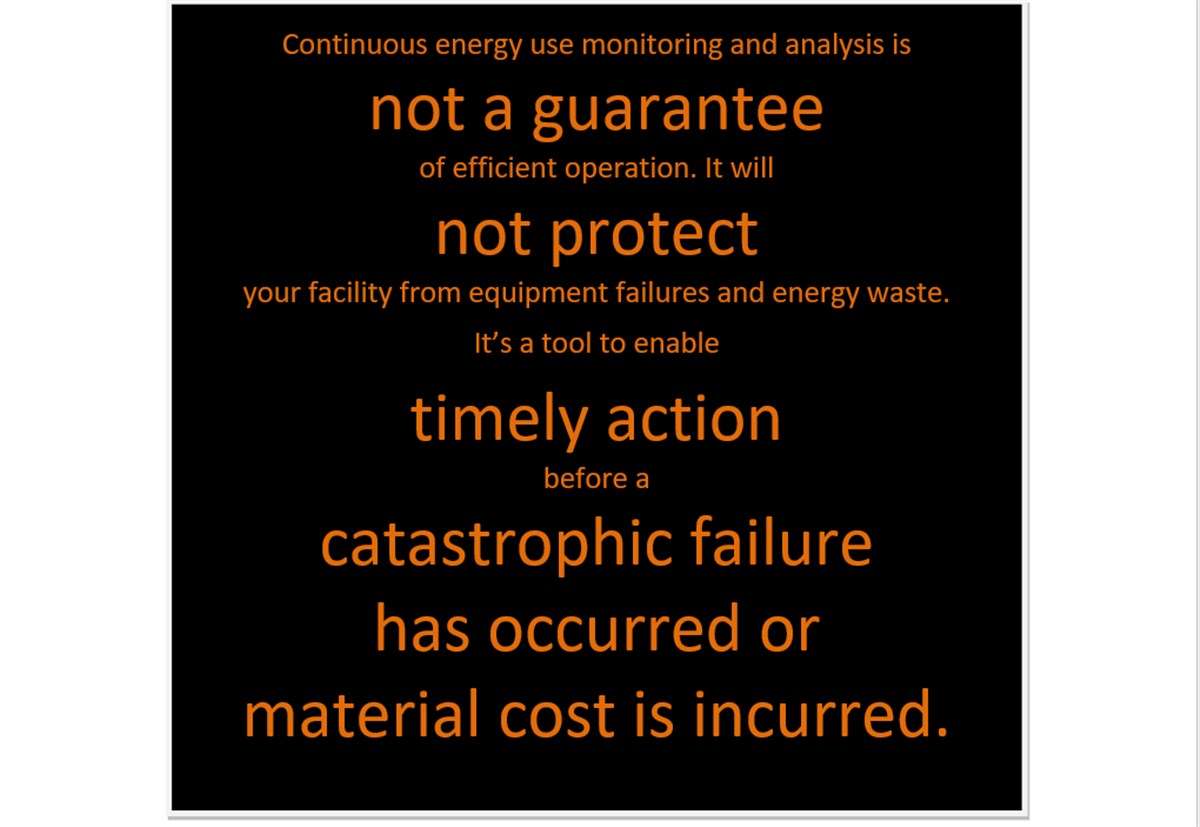

Once all three steps above are complete, it is time to act. Measuring, analysis and forecast do not cut the bill, acting on them does.

The company can purchase natural gas or electricity at the fixed prices in advance (hedge). This step puts utility procurement cost under control: with hedging company avoids buying at spot prices, which fluctuate daily and are beyond the control.

Company can postpone production order to avoid using utility at unprofitable rate. Postponing an order may cause additional cost or lost opportunities, but fulfilling it at prohibitive utility cost may cancel all future opportunities at once.

Repeating this process is crucial. All employees within the company need to be aware of the company’s energy management procedures. A failure to act by even one worker could cost the company significant profits. It only takes a few days of paying the fluctuating spot price to make a business crumble.

Leave A Comment