Project Description

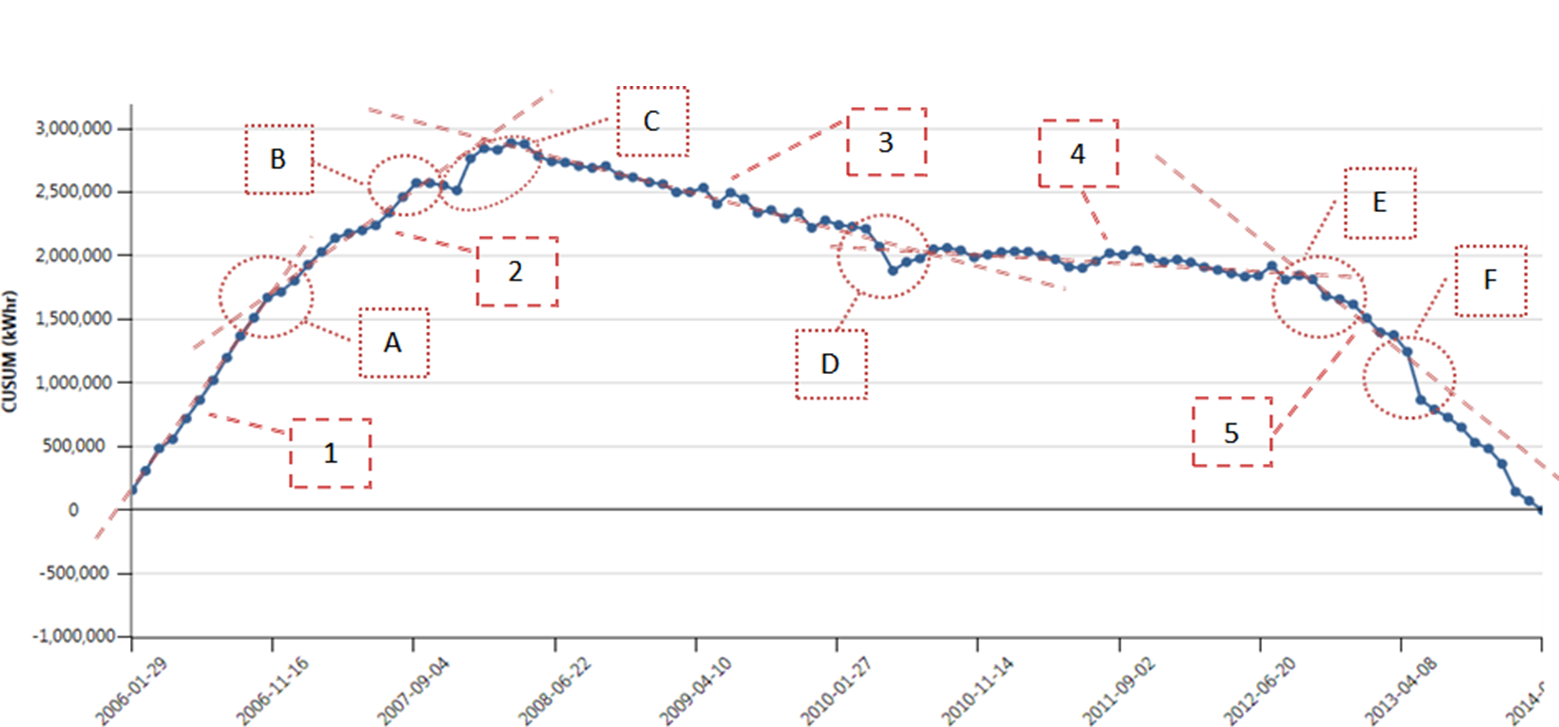

Electricity Use Analysis Quantified Unexpected Savings and Losses

GreenQ Partners analysed electricity consumption at Ready Bake Mississauga, an industrial refrigeration facility operated by Weston Foods. We used utility bill data to confirm the effects of technological and operational changes in electricity use. As usual, we used weather data provided by NASA.

We identify savings in kWh. To convert saved energy to dollars we were forced to use an average cost per kWh. This limitation was imposed by currently available usage data. Since higher consumption at a refrigeration facility coincides with higher daytime rates, actual dollar savings are even higher.

Two surprising findings of this analysis were that (a) up to 90% of electricity used at an industrial food refrigeration facility were actually not related to weather, and (b) hiring a new general manager may turn out to be as financially effective as performing a lighting retrofit.

Analysis confirmed:

Recommendations

- $30,000 per summer can be saved through more accurate control of refrigeration temperatures

- 85-90% of consumption is caused by internal heat loads – lighting, in-fridge transport, cooling of walls facing office or production space. Every action aimed to decrease these loads will pay back twice – through direct savings and through refrigeration savings

- Sub-metering of refrigeration equipment is required to evaluate its efficiency