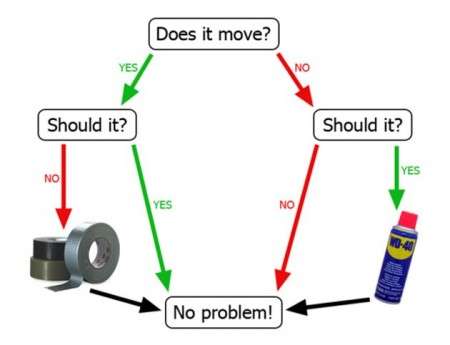

An old engineering joke says that if it moves, but should not – use duct tape, if does not move, but should – WD-40. Though every joke contains a joke, this formula can be applied to a walk through energy audit: engineering knowledge and common sense will go a long way in identifying low hanging fruits of energy management.

Here are some examples of questions a good maintenance engineer should ask while walking the production floor:

Right now, given the time, stage of production process, ambient temperature, season, etc,

Should this

- Light (fan, motor, freezer, heater, AC) be ON or OFF?

- Heater be even powered or connected to the heating line?

- Pipe be cold or warm? Dry or wet?

- Door (window) open, closed or locked?

- Vent open or closed? Louver open or closed? Can it be opened or closed at all?

- Air go in or out of this door?

- Fan be directed here or there?

- If pipe is dry but rusty, should water condensate on it from time to time?

- What makes this noise? Should this noise be as uneven as it is?

This is indeed not a complete list of questions, though I hope it gives an idea on how simple questions can help identify issues, reduce risks and cut costs.

If everything looks alright, a diligent maintenance manager may dig deeper to find out

- what procedure or technology or which person ensures that this state is maintained?

- how is this condition monitored?

- if situation changes will manager knowing about it?

And my favourite, ultimate pair of questions:

If situation is not as it should be, what does it cost the company in energy, safety, quality, productivity, reliability?

How much will it cost to fix?

Leave A Comment